The operating characteristics of the traditional spring loaded safety valve as reflected in the certified values of minimum overpressure, blowdown and maximum allowable backpressure, are limiting more and more frequently both the design and operation of pressure vessels.

The pilot operated safety valve offers a definitely superior performance, which – coupled with its perfect tightness – grants considerable savings 1) in the design and 2) in the operation of the plant itself.

Suitable arrangement or adjustment allows the pilot operated safety valve to function properly even it the inlet pressure drop is very great. Thus it is the most inexpensive solution in cases where the spring loaded safety valve cannot cope with the pressure loss between the protected vessel and the safety valve.

The possibility to easily check and adjust blowdown, besides set pressure, at the test bench is another asset specific to the pilot operated safety valve and one which contributes to the safer operation of pressure vessels.

The main features of the pilot operated safety valves can be summarized as follows:

- Valves of a much larger size and higher set pressure than foreseen for spring loaded valves are available.

- The actual flow rate can be tailored to the requested capacity, by restricting the flow area and/or by using valves with modulating action.

- Operation is independent of backpressure even it as high as 80%.

- Remote pressure pick-up renders the valve independent of inlet pressure drop.

- The valve is perfectly tight at a pressure as high as 95% of set pressure.

- The required overpressure is very low (1% to 5% depending on the type of pilot).

- The checking and adjustment of both set pressure and blowdown are very easy.

Advantages of TAI Milano pilots:

- There are no gaskets or seals on any adjacent sliding surfaces of pilots 601, 701 and 90, and therefore there is no friction which could affect the opening sensing pressure.

- The materials / surface conditions of adjacent sliding parts differ from each other and are selected to avoid the risk of seizure.

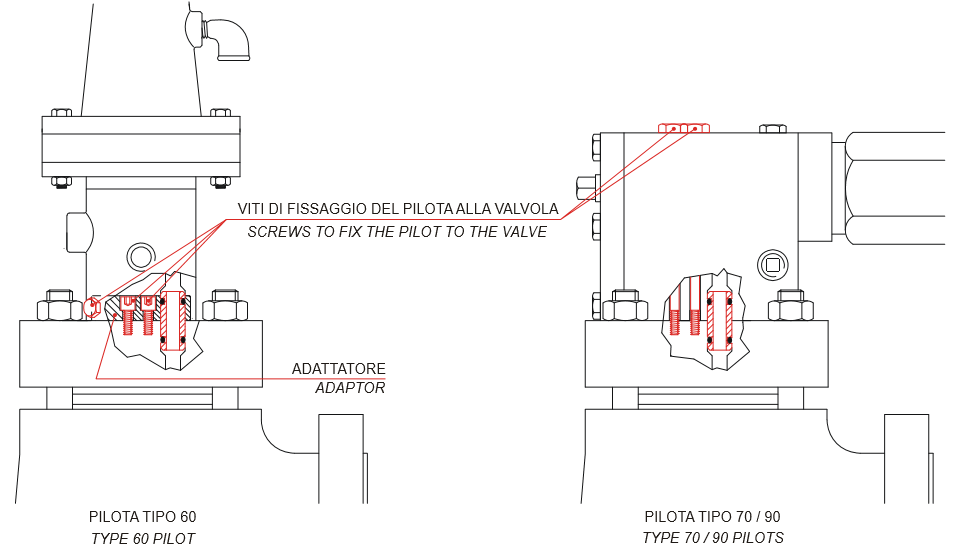

- The pilot is mounted directly on the valve cover by means of one hollow pin and is fixed with screws (see figure below). Thus external connections (mechanically weak and prone to leakage) are avoided.

- The specific characteristics mentioned above guarantee repeatability of operation, maximum sturdiness and simplified maintenance, i.e. safety.

In order to satisfy all possible requirements relative to the physical state of the medium, and to the action (on/off or modulating) and pilot type (flowing, non-flowing), we offer five different pilots, which conform to the specifications shown in table on page 10 in catalogue.

Pilot 701 is patented. For pilot 703, the request of patent has been presented.

| Range | Availability |

| Size | ->= 14″, Orifice D to V |

| Pressure | 0,01 to 520 barg |

| Temp, C | -196 to + 250 |

| Overpressure | 1 to 5% |

| Ends | Flanged |

| Materials | CS- SS- Duplex- SuperDuplex- 6Mo- Titanium |